THE PROJECT

For years, Kessler Process Automation has been supplying comprehensive and customized electrical and automation solutions for state-of-the-art industrial processes. From large power plants to industrial pilot plants, we are able to fully cover the broad spectrum of process control technology.

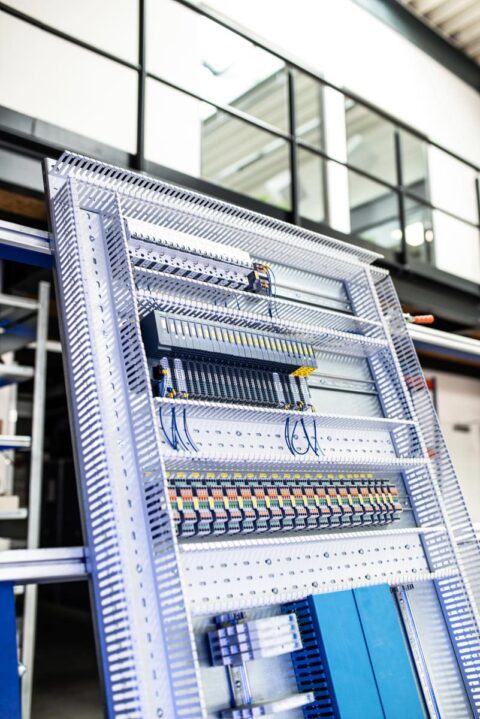

Like many around the world, the Luxembourg-based company Paul Wurth relies on the long-standing expertise of our Echternach team when it comes to the latest development for automated CO2-reduction within the steel-production industry, the Luxembourg company Paul Wurth relies – just like many others worldwide – on the long-standing competences of our team in Echternach. The holistic cooperation between all of our departments in the areas of assembly, control cabinet construction, programming, DCS installation and project management makes us the right partner – we implement the particular wishes specified for this customized industrial pilot plant exactly in accordance with the customer’s expectations. The considerable knowledge and expertise of our engineers enables us, with the aid of the Siemens TIA Portal and Siemens WinCC, not only to develop individual, complex, efficient and highly scalable DCS software libraries for our customers but also to design a plant of a kind that has never been seen before. And we can do this within a very small space, since the pilot plant for automated CO2-reduction is housed within a container. A truly compact solution that leaves nothing out!2-Reduktion ist in einem Container stationiert. Eine wirklich kompakte Lösung, bei der an alles gedacht wurde!

You can learn more about our cooperation with Paul Wurth by following this link:

https://www.paulwurth.com/en/paul-wurth-and-the-steel-partners-dillinger-and-saarstahl-join-forces-on-development-of-dry-reforming-technology/